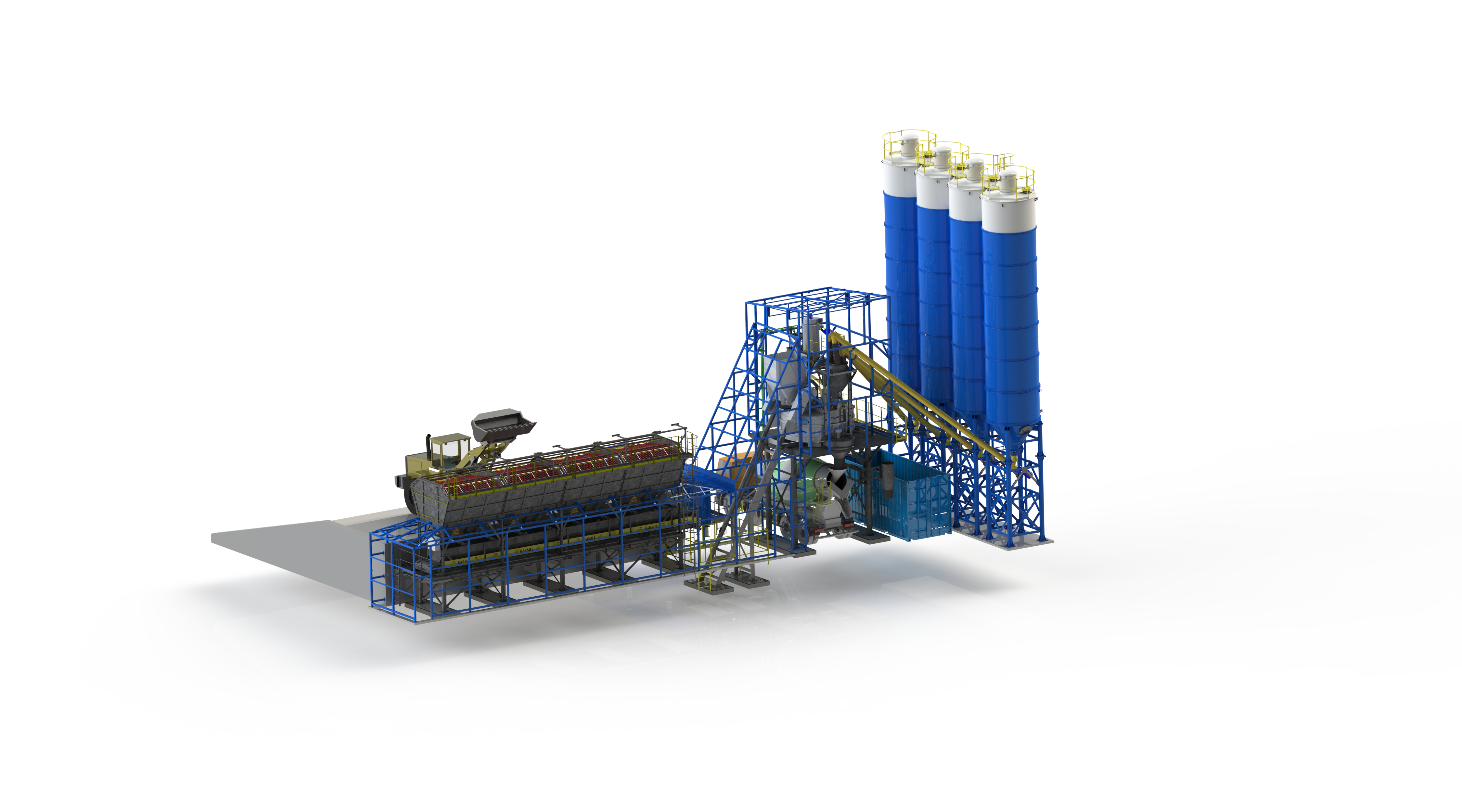

Компактне рішення для високопродуктивного бетонного виробництва

KARMEL 110С СКІП – це сучасна стаціонарна бетонозмішувальна установка, що поєднує високу продуктивність (110 м³/год), компактність і ефективність завдяки скіповій системі подачі інертних матеріалів. Завдяки автоматизованій системі управління, точному дозуванню та ефективному завантаженню компонентів, установка є ідеальним вибором для масштабного будівництва, виробництва залізобетонних виробів (ЖБІ) та дорожніх проєктів.

Основні переваги KARMEL 110С СКІП

✅ Продуктивність 110 м³/год – оптимальне рішення для масштабного виробництва бетону.

✅ Скіпова система подачі матеріалів – зниження витрат електроенергії та обслуговування.

✅ Двовальний змішувач 3,0 м³ – забезпечує рівномірне перемішування та високу якість бетону.

✅ Автоматизована система управління – точний контроль та оптимізація процесу.

✅ Компактність – займає менше місця, ніж установки з конвеєрною подачею інертних матеріалів.

Переваги бетонозмішувальної установки KARMEL 110С СКІП

1. Економічність та енергоефективність

✔ Скіповий механізм дозволяє значно зменшити витрати електроенергії.

✔ Зниження експлуатаційних витрат завдяки простішій конструкції.

2. Висока продуктивність та якість

✔ Виробництво до 110 м³ бетону на годину.

✔ Стабільна якість суміші завдяки автоматичному дозуванню.

3. Автоматизація всіх процесів

✔ Збереження понад 1000 рецептів бетону та можливість програмування нових.

✔ Дистанційне керування та контроль у реальному часі.

4. Надійність та довговічність

✔ Посилені зносостійкі компоненти для довготривалої експлуатації.

✔ Мінімальне технічне обслуговування завдяки продуманій конструкції.

5. Мінімальний вплив на довкілля

✔ Система пилозахисту мінімізує запилення та забруднення.

✔ Раціональне використання води та цементу зменшує витрати.

Де використовується KARMEL 110С СКІП?

🏗 Будівельні компанії – виробництво бетону для масштабних об'єктів.

🚧 Дорожнє будівництво – виготовлення бетонних сумішей для автострад, мостів, тунелів.

🏭 Заводи залізобетонних виробів (ЖБІ) – виробництво фундаментів, плит, блоків.

🏢 Промислові виробничі комплекси – ефективне постачання бетону для великих підприємств.

Як замовити бетонозмішувальну установку KARMEL 110С СКІП?

📞 1. Консультація: наші спеціалісти допоможуть вибрати оптимальну комплектацію.

📃 2. Підготовка проєкту: адаптація установки під ваші виробничі потреби.

🚚 3. Виготовлення та доставка: транспортування обладнання на ваш об’єкт.

🔧 4. Монтаж та налаштування: пусконалагоджувальні роботи та навчання персоналу.

🛠 5. Гарантія та сервіс: післяпродажне обслуговування та підтримка клієнтів.

📲 Зв’яжіться з нами, щоб отримати персональну пропозицію!

KARMEL – продуктивність, якість, надійність!