Стаціонарні бетонозмішувальні установки

Розрахуйте вартість будівництва з нами!

Швидкий та точний розрахунок вартості будівництва з нашим онлайн калькулятором. Не гайте зусиль - отримайте точні цифри для вашого проекту просто та швидко.

Замовити консультацію

Бажаєте найкращий бетонний завод саме для ваших потреб? Заповніть форму, та ми зв'яжемося з вами

Що таке стаціонарна бетонозмішувальна установка

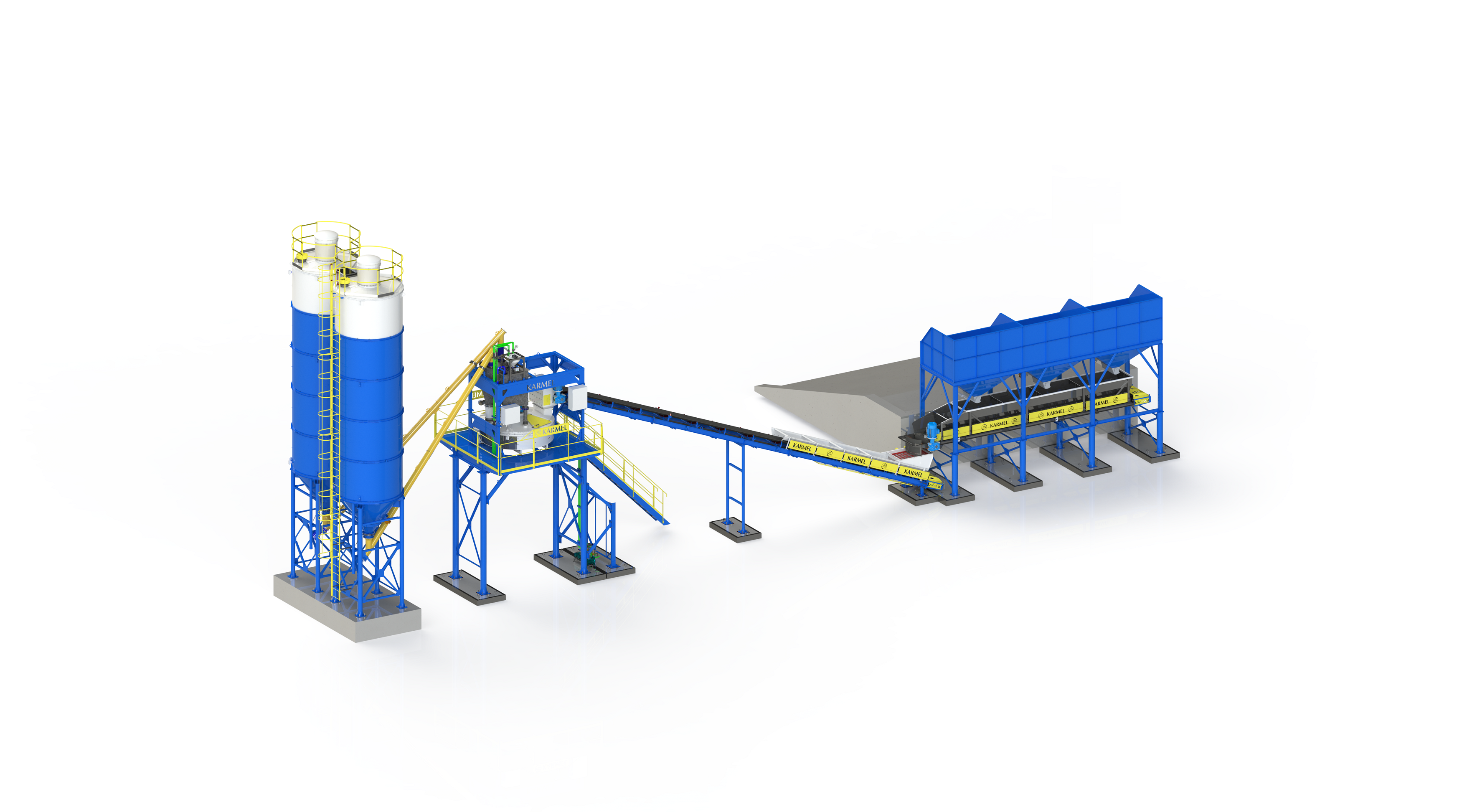

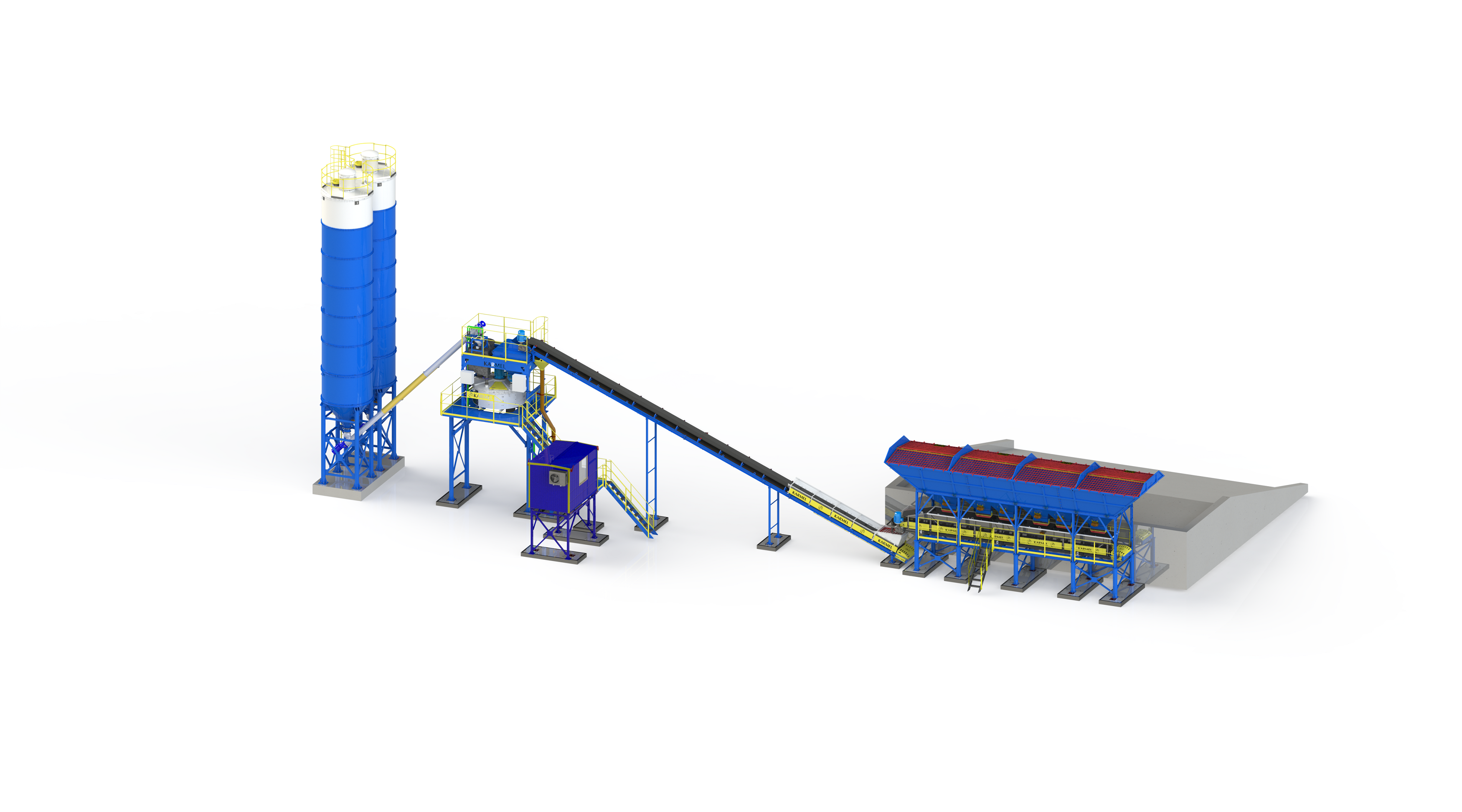

Стаціонарна бетонозмішувальна установка для виробництва бетону (скорочено БЗУ, іноді БСУ або бетонний вузол) — це комплекс машин і механізмів для приготування бетонної суміші. Вона призначена для виготовлення великих обсягів бетонної суміші з високою точністю дозування та стабільною якістю.

На відміну від мобільних бетонозмішувальних установок, стаціонарна версія не призначена для переміщення. Її головною перевагою є стабільність у роботі, тривалий ресурс служби та здатність працювати в умовах великих навантажень. Це оптимальне рішення для компаній, які виконують масштабні будівельні роботи або прагнуть створити власний завод бетону з постійною інфраструктурою.

На відміну від окремих бетонозмішувачів, які забезпечують змішування на обмеженому рівні, стаціонарний бетонний завод — це повноцінний комплекс, що включає всі етапи підготовки бетонної суміші: від приймання сировини до автоматичного контролю якості.

Для компаній, які планують інвестувати в таке обладнання, важливим фактором є ціна бетонного заводу. Вона залежить від продуктивності, комплектації та рівня автоматизації, тому варто обирати техніку з урахуванням конкретних потреб виробництва.

З яких компонентів складається бетонний завод

Стаціонарна бетонозмішувальна установка має модульну будову та складається з ряду технічних елементів, що формують єдиний автоматизований цикл. Основні компоненти:

- Бетонозмішувач — серцевина заводу, відповідає за однорідне перемішування всіх інгредієнтів;

- Система дозування — забезпечує точне зважування цементу, води, заповнювачів та добавок;

- Бункери інертних матеріалів — призначені для тимчасового зберігання піску, щебеню, гравію;

- Транспортери — скіпові або стрічкові механізми, що переміщують компоненти до змішувача;

- Силоси інертних матеріалів — вертикальні ємності для цементу та мінеральних добавок із системою пневматичної подачі;

- Система автоматизації — програмне забезпечення з сенсорним управлінням, що координує процес дозування, контролює рецептуру, веде статистику та облік.

Усі компоненти можуть бути адаптовані під потреби клієнта завдяки широкому вибору комплектуючих. Завод функціонує як єдина система, де кожен вузол відповідає за чіткий і контрольований результат.

Переваги стаціонарного бетонного заводу

Коли будівельна компанія вирішує купити бетонний завод, часто вибір падає саме на стаціонарну модель через її стратегічні переваги.

- Висока продуктивність — установка здатна виготовляти до 300 м³ бетону на годину, що критично для великих проєктів.

- Стабільна якість — автоматичне дозування гарантує постійність рецептури, незалежно від зовнішніх умов.

- Точність дозування — сучасні електронні системи мінімізують похибку до 1%, що забезпечує відповідність нормативам.

- Підходить для великомасштабного будівництва — заводи ефективні для житлових, промислових і дорожніх об'єктів.

- Інтеграція з програмним забезпеченням — можливість віддаленого керування, обліку партій та диспетчеризації

На відміну від тимчасових або мобільних рішень, стаціонарний завод — це довгострокова інвестиція в стабільність та якість.

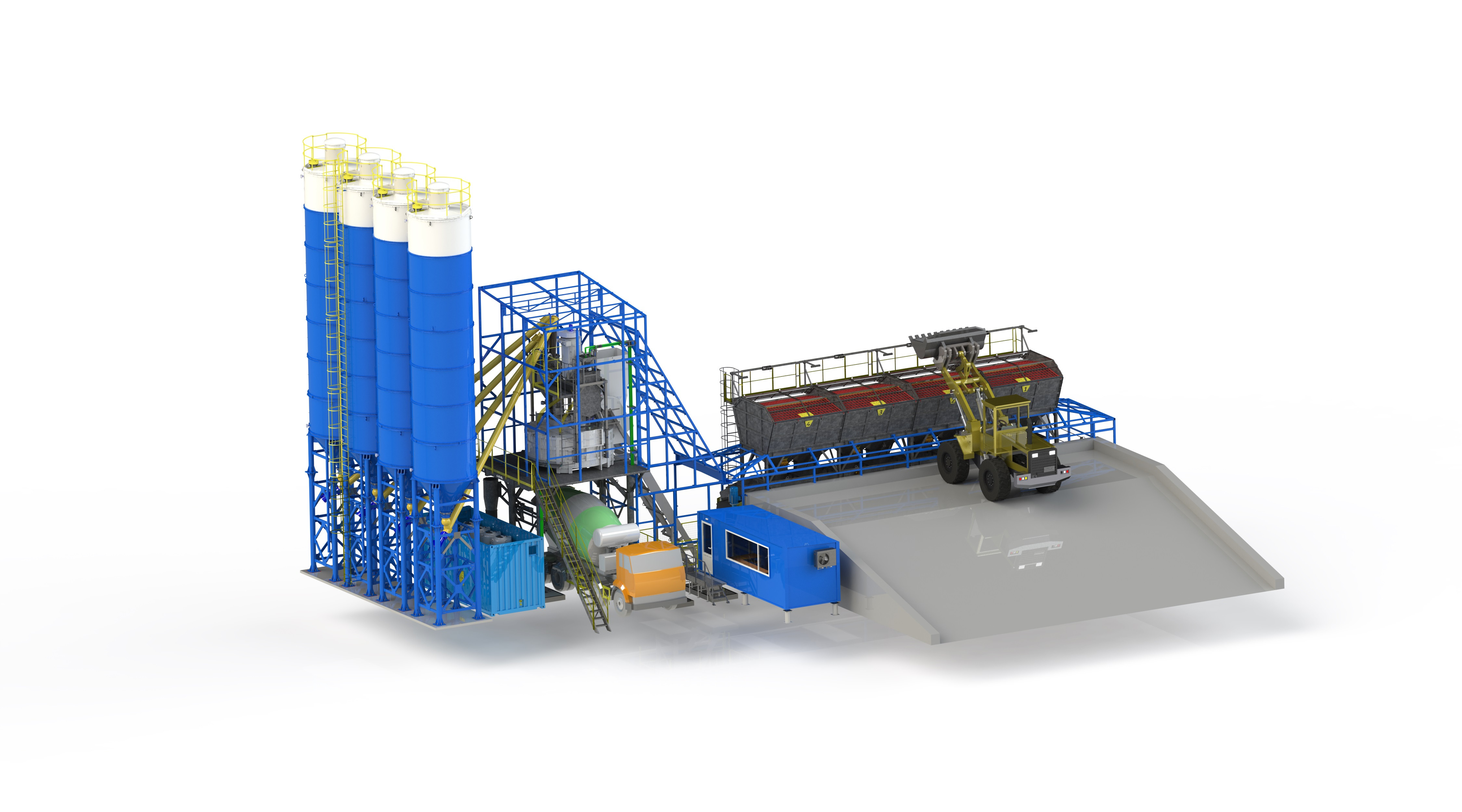

Кому та для яких задач потрібні бетонні заводи

Стаціонарні бетонні заводи використовуються підприємствами, що працюють із серійним виробництвом бетону. Найчастіше такі установки можна побачити на великих об’єктах: у дорожньому будівництві — для заливки магістралей, мостів, шляхопроводів; у зведенні житлових комплексів і багатоповерхових споруд — коли потрібна стабільна якість суміші у великих об’ємах; на промислових майданчиках — логістичні центри, склади, виробничі комплекси.

Також обладнання ефективно використовується на територіях кар’єрів, де бетонний вузол функціонує як центральна частина логістичного ланцюга. Для таких задач доцільно купити стаціонарний бетонний завод, а не орендувати, оскільки це дозволяє уникнути збоїв у постачаннях і забезпечити автономність виробництва.

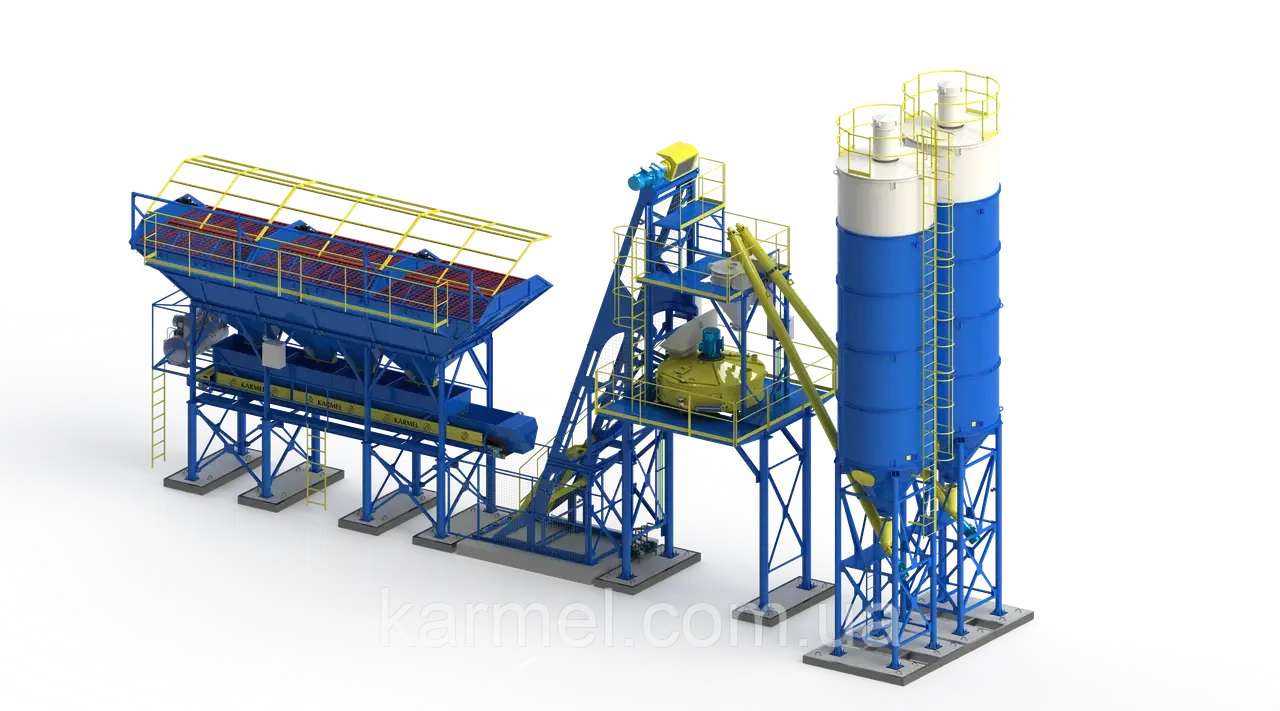

Які бетонні заводи пропонує компанія “KARMEL”

Компанія “KARMEL” пропонує великий вибір стаціонарних бетонозмішувальних установок, кожна з яких може бути адаптована під індивідуальні вимоги. У каталозі — обладнання з продуктивністю від 60 до 180 м³/год, яке комплектується планетарними або двоваловими змішувачами, системами скіпового чи стрічкового типу транспортування, а також сучасними електронними панелями керування.

Заводи “KARMEL” вирізняються:

- Модульною конструкцією, що спрощує монтаж і обслуговування;

- Надійною автоматикою для точного дозування та контролю процесу;

- Високою адаптивністю до різних типів інертних матеріалів;

- Сумісністю з більшістю сучасних рецептур бетону;

- Можливістю індивідуального проєктування комплектації.

Це дозволяє замовнику купити бетонний завод з урахуванням специфіки будівництва, логістики, рецептур та особливостей ділянки.

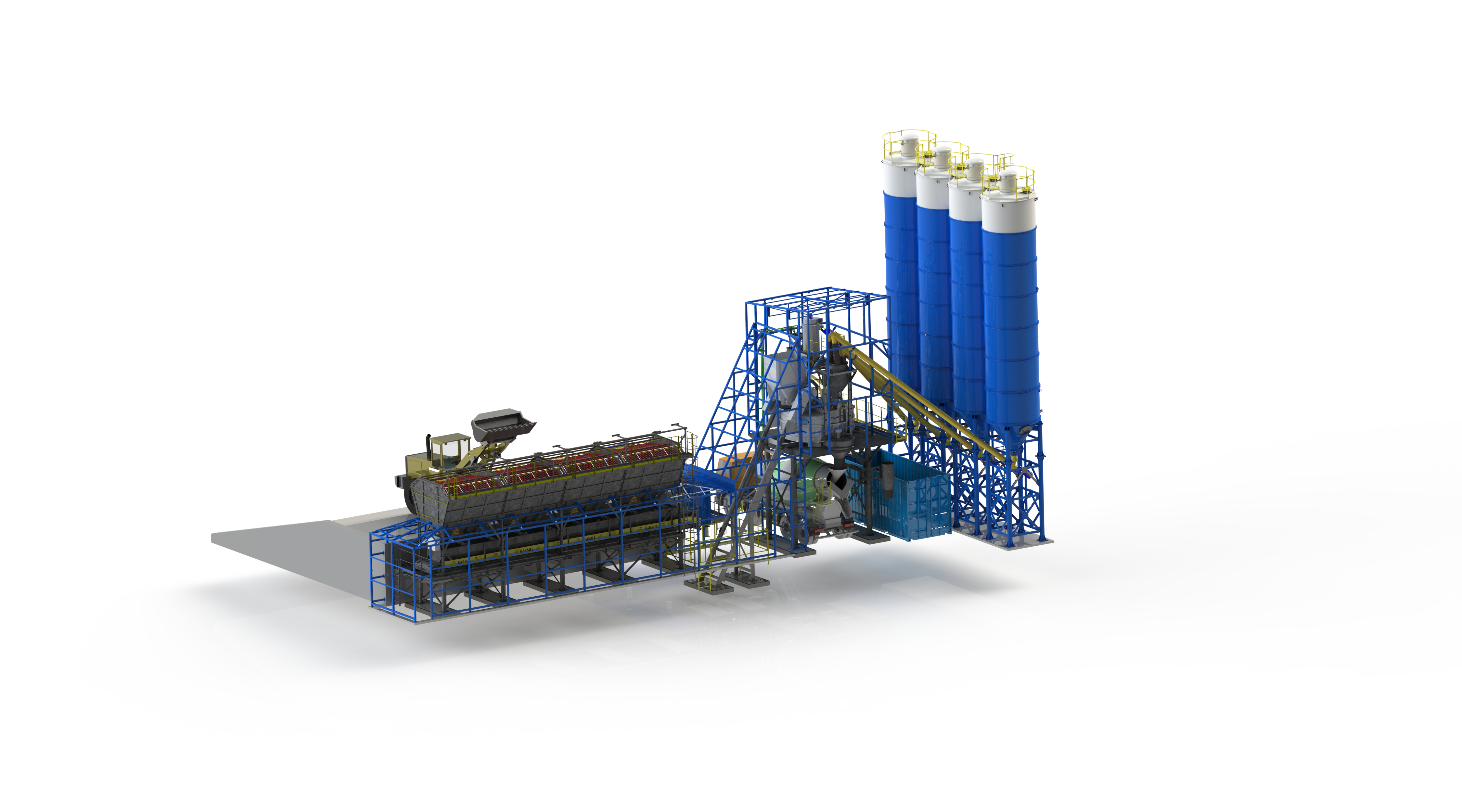

Чому варто замовити бетонний завод у “KARMEL”

Обравши компанію “KARMEL”, ви отримуєте не просто надійне обладнання, а повноцінне інженерне рішення. Виробництво заводів відбувається в Україні з контролем якості на кожному етапі. Команда технічних фахівців супроводжує клієнта від проєктування до запуску.

Переваги співпраці з “KARMEL”:

- Власне виробництво: компанія гарантує якість, відповідність технічним характеристикам і контроль на кожному етапі.

- Проєктування “під ключ”: “KARMEL” бере на себе всі етапи — від креслень і комплектації до монтажу та запуску.

- Навчання персоналу та техпідтримка: інженери навчають операторів, допомагають з налаштуванням і супроводжують у процесі експлуатації.

- Оперативне постачання запчастин: складські запаси дозволяють швидко забезпечити ремонт і технічне обслуговування.

- Гнучка ціна: вартість залежить від конфігурації, продуктивності та додаткових опцій — ви платите тільки за потрібне.

Готові інвестувати в надійний, потужний і довговічний інструмент для власного виробництва бетону? Оберіть професійний підхід — купіть бетонний завод у “KARMEL”.